SIG’s .277 Fury and Barrel Burnout

SIG’s new .277 Fury cartridge and Cross rifle have raised the issue of barrel burn out because the SAAMI specified maximum average chamber pressure for the round is an unheard of 80,000 psi. But will that really make a difference?

Shooters are curious because the allure of the .277 Fury is enhanced performance. This steel-headed cartridge is a modified, necked down 308 Winchester, yet delivers from a 16-inch barrel what the old 270 Winchester does from a 24-inch barrel. Add a suppressor to a 16-inch .277 Fury barrel and you’re hunting rig is still two inches shorter than your old 270. And you won’t blow out your eardrums with each shot. Nice. But, at 80,000 psi, how many shots will that barrel take before it scatters shots like a 12 gauge?

The .277 Fury is the 308 Winchester case with the shoulder pushed slightly forward, sidewalls less tapered, and a steel head. With such a small powder capacity, will the higher maximum average chamber pressure of 80,000 psi radically increase barrel wear?

In a recent You Tube video I discussed a fan’s assessment of 80,000 psi exacerbating barrel burn out. He had a novel idea about bullet weight contributing to the erosion. I also addressed conventional wisdom on the phenomenon plus some conjectures of my own. Perhaps you could check it out and share your insights. I’ve yet to interview engineers on the topic, but even after I do, I’ll enjoy hearing conjecture and experiences from other hunters, shooters, and gunsmiths, so send yours in. The core question is whether 15,000 psi more pressure than our current high pressure cartridges put out will radically increase barrel wear.

I’ll admit I don’t know absolutely why and how barrels burn out because the whole business is clouded by myth and mystery. Decades ago I assumed, like many, that the friction of bullets ripping along the twisting grooves and lands of a rifled barrel literally wore it down. But formerly accurate barrels that no longer shoot tight groups almost always have deep, sharply edged lands and grooves at the muzzle and deep down the tube until the final inch or two before the rifling tapers into the unrifled leade or throat. Here there be monsters! Fire-breathing monsters. Or at least evidence of their passing.

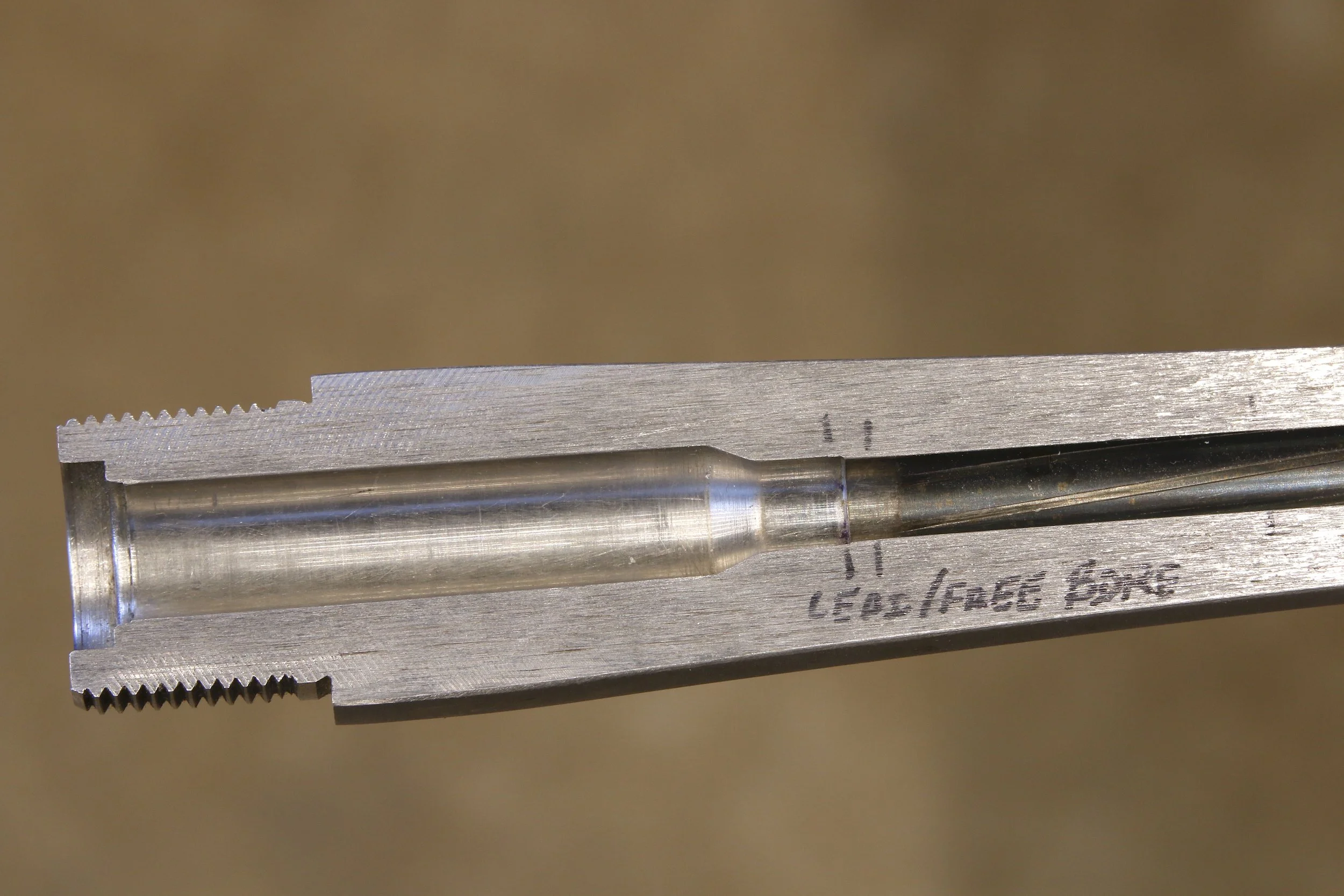

In this cutaway rifle barrel you can see where the unrifled throat in front of the case mouth ramps up to the start of the bore and its rifling grooves. This is the area where flame temperature and gas velocity are highest. It’s also where firecracking begins.

It is this leade or throat at the neck of the chamber where the steel “burns out.” Here, where burning powder drives flames as hot as 5,000-degrees F., steel begins to crack. Cracks become crevasses, then canyons looking like grandma’s sidewalk sidewalk poured back in 1935. This fractured leade gapes like the maw of a great white shark ready to rip and mangle the hide of every bullet sent its way.

Barrel makers will assure you the tube they carefully bored, rifled, honed, and chambered did not originally look that way. What happened? A deadly mix of substance abuse (chemical erosion) and overheating. As discussed in the embedded video, the heat from rapidly burning gunpowder weakens the barrel steel. The larger the powder supply and narrower the bore, the more concentrated the flame. The longer the string of shots and the more quickly they are fired, the hotter the steel becomes. The hotter it gets, the faster it crumbles under subsequent shots.

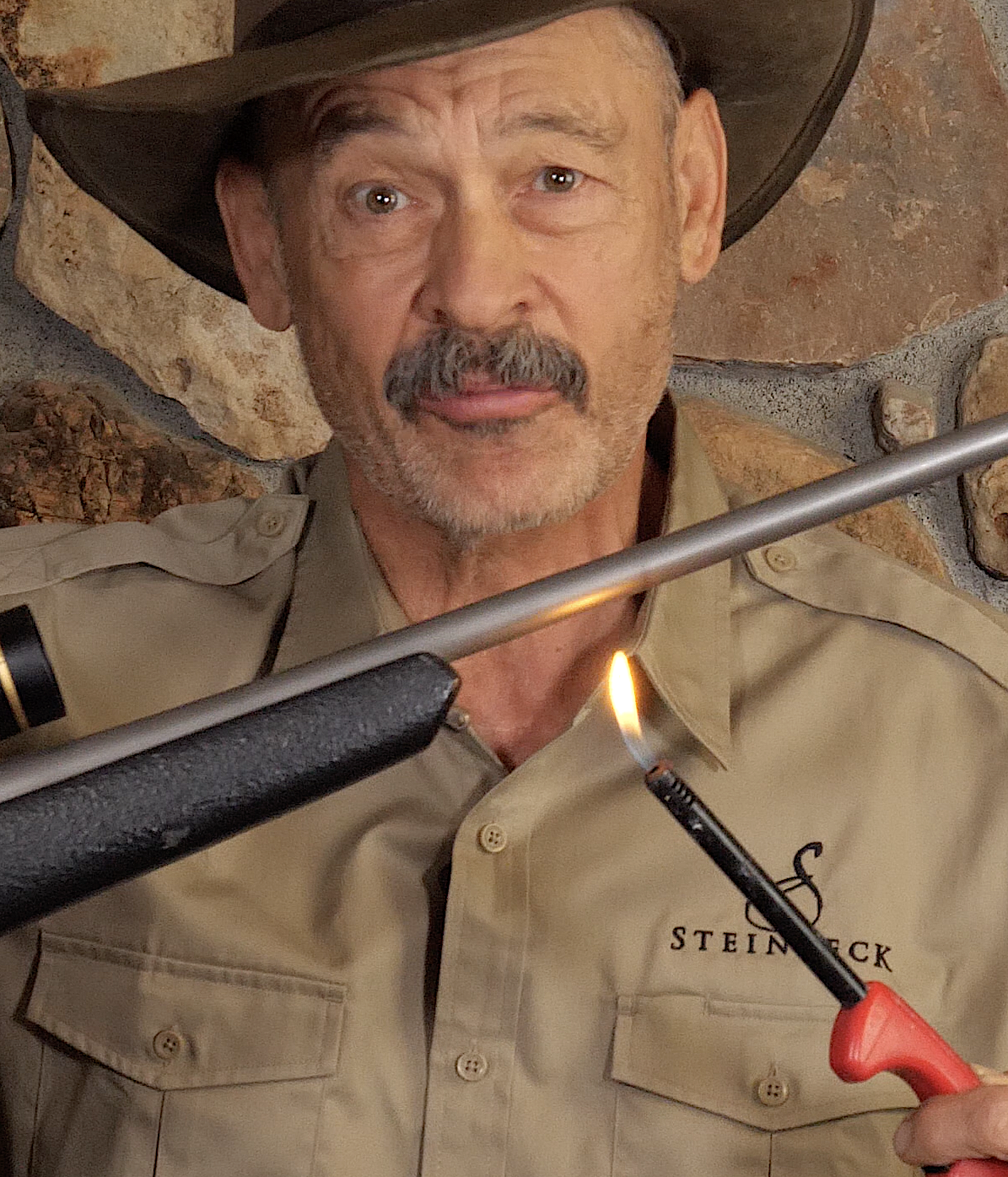

The 1,400 F. temperature of this flame is cool compared to the 3,300- to 5,500 F. temperature at the mouth of a just-ignited centerfire rifle cartridge.

Simultaneously, chemical reactions from the burning powder and its many additives begin eating away at the steel. As cracks widen and deepen, gasses at hot as 5,000 F. jet and cut. Tiny particles of unburned powder abrade like sandblasting. The result is often called, aptly if not perfectly, fire cracking.

The puzzling question is how much chamber pressure contributes to all this. Certainly pressure does not “eat away or abrade” barrel steel. And if barrel steel is thick and strong enough to withstand rupturing under the explosive pressure, how does it “wear out” from pressure? My theory is that high chamber pressure forces the steel to expand ever so slightly. It contracts as it cools. Heat makes the expansion easier, so the faster you shoot repeatedly, the greater the expansion and contraction. Fissures open and barrel burn out is well underway. Heat and pressure, then, seem manifestations of the same thing.

Cracks and fissures at the throat and leade are classics signs of a “burned out” barrel. This is usually confined to the leade and an inch or so farther down the bore.

So how much faster will a .277 Fury barrel wear out? Certainly 80,000 psi argues for early break down, but small powder volume argues against it, as suggested by my comparisons of various cartridge max chamber pressures and powder volumes. By reputation the 220 Swift burns out barrels faster than the 22-250, yet the latter is rated 65,000 psi, the former just 62,000 psi. But the Swift burns slightly more powder than the 22-250. You see the same relationship between the 270 Win. and the 270 Wby. Mag. I don’t think anyone believes the smaller powder capacity 270 Win. will burn a barrel out as quickly as a 270 Wby. Mag., yet max chamber pressure in the Winchester is 65,000 psi, in the Weatherby 62,500 psi. But a 3,000 psi differential is much less than a 15,000 psi differential.

The .277 Fury adds 15,000 psi to the max average chamber pressure of the 270 Win. on left and 27 Nosler on right, but they each burn more powder. Which contributes more to throat erosion and barrel burnout?

Yet another aspect of barrel erosion is a powder’s burning temperature and rate. Some powders burn more cooly than others. Some burn more slowly, thanks to a combination of shape (surface area) and inhibitors. And some additives such as titanium dioxide enhance barrel hardness by nitriding them. SIG is reportedly working with some special blends of cool burning powders, so they’re apparently onto something.

A final question is the military application and selection. SIG developed the .277 for the U.S. military. And not just for a standard issue carbine, but for machine guns. Would the Army select a cartridge with rapid throat eroding qualities?

SIG’s commercial Cross rifle in .277 Fury could be considered “just a bolt action” in disguise, but behind that folding stock and barrel shroud sits an action specially built and tested to handle the 80,000 psi chamber pressures of this hot new cartridge. How much this high pressure will contribute to barrel burnout remains to be seen.

Clearly there is a lot more to barrel burn out than just pressure or flame temperature. How all this will effect the life of .277 Fury barrels and any subsequent high pressure cartridges that might arise remains to be seen. I’ve a hunch 80,000 ps will not be a flash in the pan. Nor will it likely be the end of the line. There are rumors of experimental cartridges and rifles at max chamber pressures above 120,000 psi! The times they are achangin’.

How to Extend Barrel Life

There’s an easy way to prevent barrel burnout: don’t fire the rifle. Some gun collectors choose this route, but most of us buy rifles to shoot. Many limit their shooting, perhaps firing one shot to confirm zero, then taking another to bag their annual venison. To my way of thinking that’s like buying a 4x4 truck and driving it to town once a month for supplies.

Rifles are tools. They are designed to throw precision projectiles either to hit a target or render game ready for quartering and packing out. In order to do either, you must shoot. But you can do it judiciously and minimize throat erosion.

First, resist shooting a hot barrel. Let it cool between shots. Of course you’ll need to shoot quickly on some hunts, especially hog culling operations, but you needn’t rapid fire while target shooting or working up loads.

Many shooters are convinced that ground squirrel infestations are the real cause of barrel burnout.

Second, consider building light loads for practice. Reducing powder charges by 3 to 10 grains will moderate pressure, heat, and gas cutting. This doesn’t work for learning drops and drifts, but it’s fine when working on handling efficiency, shooting positions, flinch control, and trigger control.

Third, research powders and try cooler burning ones.

Fourth, don’t get overstressed about barrel burn out. Barrels are like truck tires or spark plugs. They wear out. They can be replaced. So use your tools. Shoot. Enjoy.

# # #